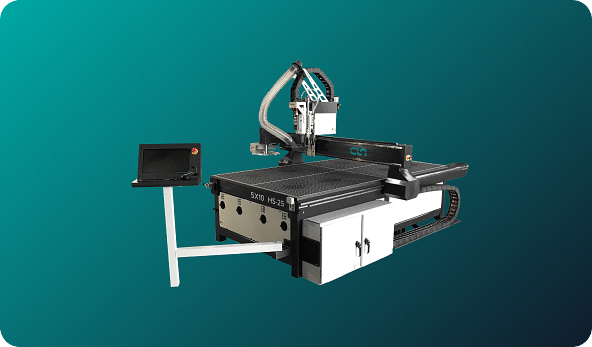

HS-25

The workhorse that built the brand.

CNC Router Table HS-25

- Entirely Made in the United States

- Fully Welded Steel Frame

- 4x8, 5x10, 6x12 Standard Table Sizes

- Custom Table Sizes Available

- 6” Standard Z Clearance (Increased Clearance Available)

- Automatic or Manual Tool Change HSD Spindle

- Carousel or In-Line Tool Changing Capabilities

- American-Made Servo Drives and Servo Motors

- Up to 3,500 IPM Rapid Movements

- Helical Nickel-Plated Rack and Pinion X, Y Axis

- Precision Ball Screw Z Axis

- 4+ Zone Vacuum System

- 2HP – 10HP Dust Collection Options Available

- Onsite Training Available

- Annual Service Package Available

- 100% Free Dedicated Remote Technical Support for Life of the Machine

Financing Available

Ask About CNC Machine Financing Options.

We want to help your business realize its potential.

Get A QuoteCNC Router Table HS-25: Precision Engineering Meets High-Volume Productivity

The CNC Router Table HS-25 from CLN of South Florida is a professional-grade cutting system engineered to deliver exceptional accuracy, power, and adaptability for even the most demanding fabrication environments. Designed with industrial users in mind, this model combines structural integrity, advanced automation, and operator-friendly controls to streamline workflow and maximize productivity.

Heavy-Duty Frame and Custom Sizing Options

At the core of the HS-25 is a fully welded steel frame, providing the structural stability necessary for precise and consistent routing across various materials. Unlike bolted or modular designs, the solid welded frame resists vibration, ensuring smoother operation and more accurate results over time. Whether you're working in cabinetry, signage, aerospace, or other high-demand industries, this robust construction helps maintain quality through long production runs.

The HS-25 is available in multiple standard bed sizes, including 4x8, 5x10, and 6x12 formats. For businesses with unique space constraints or workflow requirements, CLN also offers custom bed sizes tailored to your shop’s exact specifications.

Advanced Table Features for Precision and Control

The router’s phenolic table top offers a strong, low-friction surface that resists wear and warping while supporting smooth material handling. Paired with an integrated vacuum pump hold down system, your workpieces stay firmly in place during machining, even under high-speed operations or intricate tool paths.

Pop-up stops are built into the table design to assist with quick, repeatable material placement—ideal for operators who demand both speed and precision in everyday production.

With a gantry clearance between 6 and 8 inches, the HS-25 also accommodates thicker stock and more complex three-dimensional applications without sacrificing accuracy.

Automated Tool Management for Efficient Operation

The HS-25 CNC Router Table features a high-capacity tool changer system to reduce downtime and boost efficiency. Depending on your shop’s needs, it can be configured with either an in-line or carousel tool holder. Both options are designed for quick, seamless switching between bits, allowing you to complete complex jobs without manual tool changes.

This level of automation is especially valuable in large-scale production environments, where minimizing interruptions can significantly improve throughput and job turnaround times.

Smart Lubrication and Chip Collection Systems

A built-in auto-misting lubrication system keeps cutting tools cool and work surfaces clean, extending tool life and improving cutting quality. This system activates only when needed, reducing unnecessary fluid use and keeping maintenance low.

To maintain a clean and safe work environment, the HS-25 also includes an integrated chip collection system that efficiently captures debris during operation. This reduces wear on components, prevents clogging, and minimizes cleanup at the end of each shift.

User-Friendly Control and Operation

Controlling the HS-25 is intuitive and operator-friendly thanks to its handheld pendant interface. This portable control device allows users to easily adjust machine settings, jog axes, and initiate job sequences without needing to return to a stationary terminal. The pendant adds flexibility to the workspace and makes machine setup or mid-job adjustments faster and more convenient.

Ideal for High-Volume Production and Custom Fabrication

Whether you're managing batch production, tackling custom builds, or running multiple complex jobs back-to-back, the CNC Router Table HS-25 offers the power and adaptability to keep up. Its combination of precision control, automation features, and robust construction make it a go-to solution for professionals in woodworking, plastic fabrication, aluminum routing, and more.

Key Features at a Glance:

- Welded steel frame for stability and long-term durability

- Available in 4x8, 5x10, and 6x12 sizes (custom options available)

- Phenolic table top for smooth and durable work surface

- 6–8" gantry clearance for thicker material handling

- In-line or carousel tool changer for automatic bit switching

- Vacuum pump hold down system for secure material placement

- Auto-misting lubrication system for improved tool performance

- Integrated chip collection system for clean operation

- Pop-up stops for repeatable positioning

- Handheld pendant for convenient operator control

CLN of South Florida stands behind the HS-25 with expert support, customization options, and a commitment to helping businesses grow through better equipment. Contact us today to learn more about how this CNC router can elevate your operation.

Let's Talk

What Can We Do To Help You Get To The Next Level

Get in Touch:

-

Corporate: 866-264-6694

-

Sales: 561-996-5900

-

Address: 2336 Cypress Ln

Belle Glade, FL 33430