Fastening Equipment

Fastening Equipment

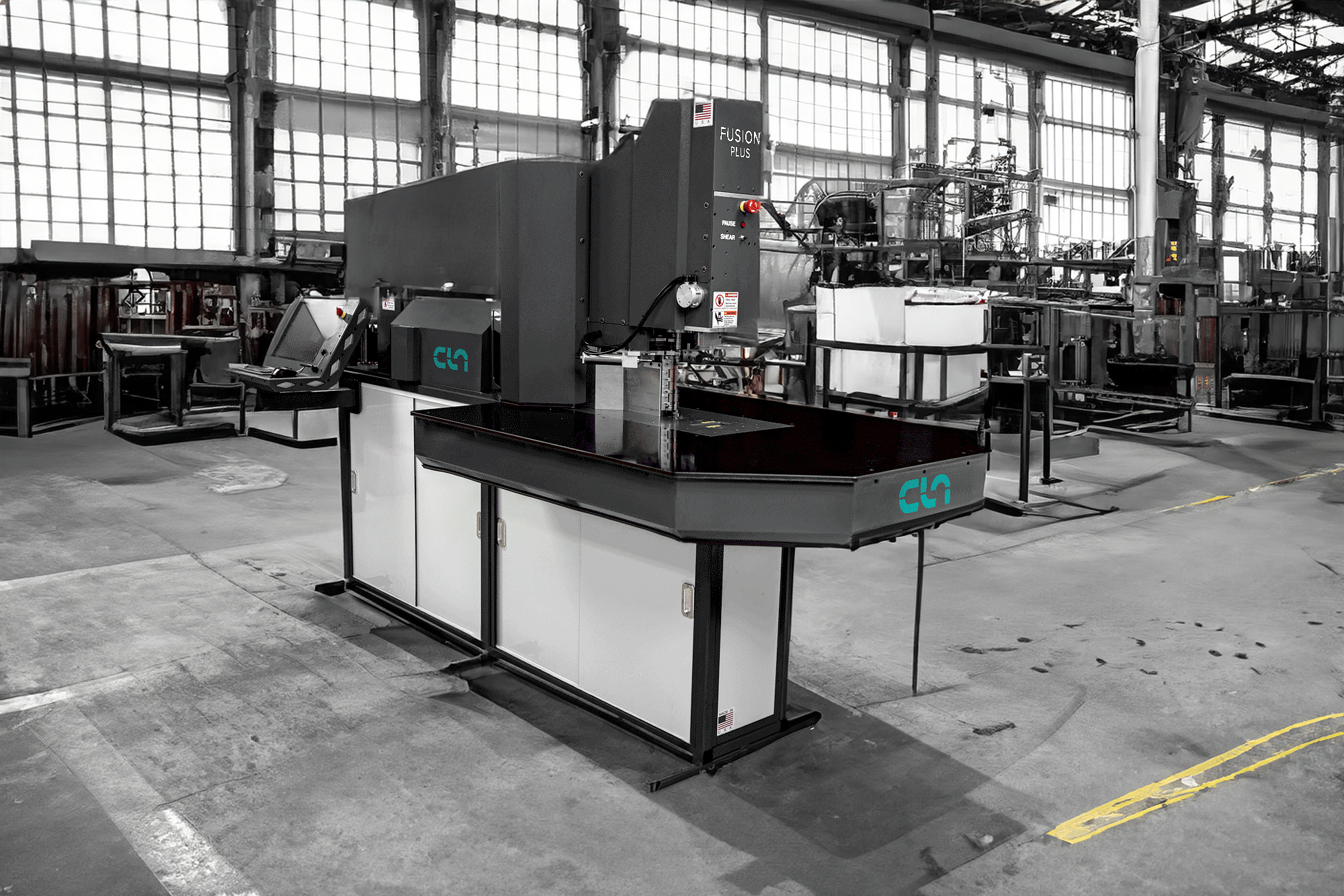

In our pursuit to offer a full spectrum of high-quality signage production tools, CLN of South Florida proudly presents an exclusive range of fastening equipment designed by the pioneers at Norlok Technology, Inc. As the first to design and manufacture clinching machines, Norlok has set the standard for efficient and reliable fastening solutions in the signage industry.

LetterLok 1200

The LetterLok 1200 is a compact fastening machine with a 12" throat, perfect for smaller signmaking spaces. It can handle up to a 6" deep return and fasten materials up to 0.125" thick. Equipped with an optional Self-Piercing Rivet (SRP) tool, it allows for precise fastening of aluminum composite and polycarbonate materials.

LetterLok 4000

The LetterLok 4000 is a robust channel letter fastening machine with a 25" throat, perfect for handling up to 10" deep returns and fastening material up to 0.160" thick. It can be equipped with a Self-Piercing Rivet (SRP) tool, ideal for securing aluminum composite and polycarbonate materials. This machine is an excellent choice for businesses seeking efficiency and precision in their signmaking processes.

Return Fasteners

Improve the efficiency and quality of your channel letter assembly. The LetterLok 3000 eliminates the need for time-consuming drilling or pop riveting, providing a fast, secure, and UL-recognized method for fastening channel letter returns, which is crucial for creating durable and visually appealing signs. The LL 3000 Mobil Cart enhances this process by allowing easy transportation of the tool, enabling signmakers to work more flexibly across larger production spaces. Together, they streamline sign fabrication, saving time and reducing manual labor.

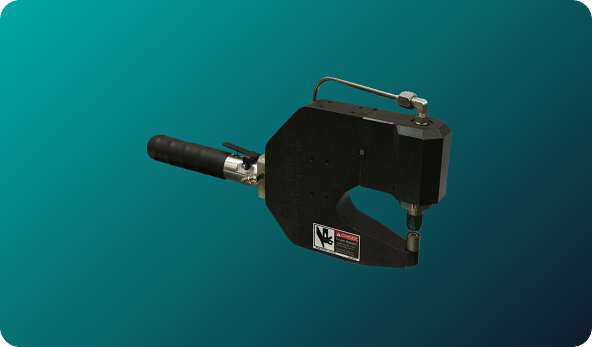

LetterLok 3000 Return Fastener

The LetterLok 3000 is a hydraulic-powered hand-held seam closer designed to securely fasten the open ends of channel letter returns. This tool eliminates the need for drilling or pop riveting, allowing for efficient, clean fastening with just two pieces of aluminum. It's perfect for signmakers seeking a fast, UL-recognized solution for closing open letter returns.

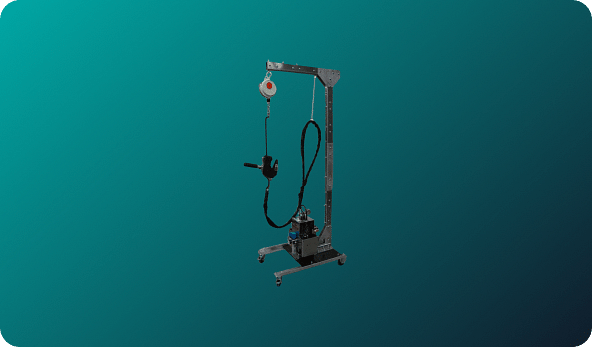

LL 3000 Mobil Cart

The LL 3000 Mobil Cart is a sturdy, all-steel welded cart designed specifically to support and transport the LetterLok 3000 return fastener. Its perfect balance makes it easy to move the tool across various work environments, improving efficiency. Ideal for signmakers, this cart enhances mobility and convenience when working with the LetterLok 3000.

More Information

Fastening equipment, such as clinching machines, is used to securely join sheet metal or other materials without the need for welding or screws. It is widely used in HVAC, automotive, and metal fabrication industries.

We offer a range of clinching machines and fastening systems that include both manual and automated solutions, ideal for various production scales.

Clinching machines eliminate the need for additional hardware like screws or rivets, reduce material costs, and provide a clean, secure, and maintenance-free joint.

Absolutely. Our fastening equipment can be customized to accommodate unique production requirements, including varying material thicknesses and joint strengths.

We provide full support, including user training, ongoing maintenance advice, and a reliable supply of replacement part sources to ensure maximum uptime and performance.

Let's Talk

What Can We Do To Help You Get To The Next Level

Get in Touch:

-

Corporate: 866-264-6694

-

Sales: 561-996-5900

-

Address: 2336 Cypress Ln

Belle Glade, FL 33430