Sign Making

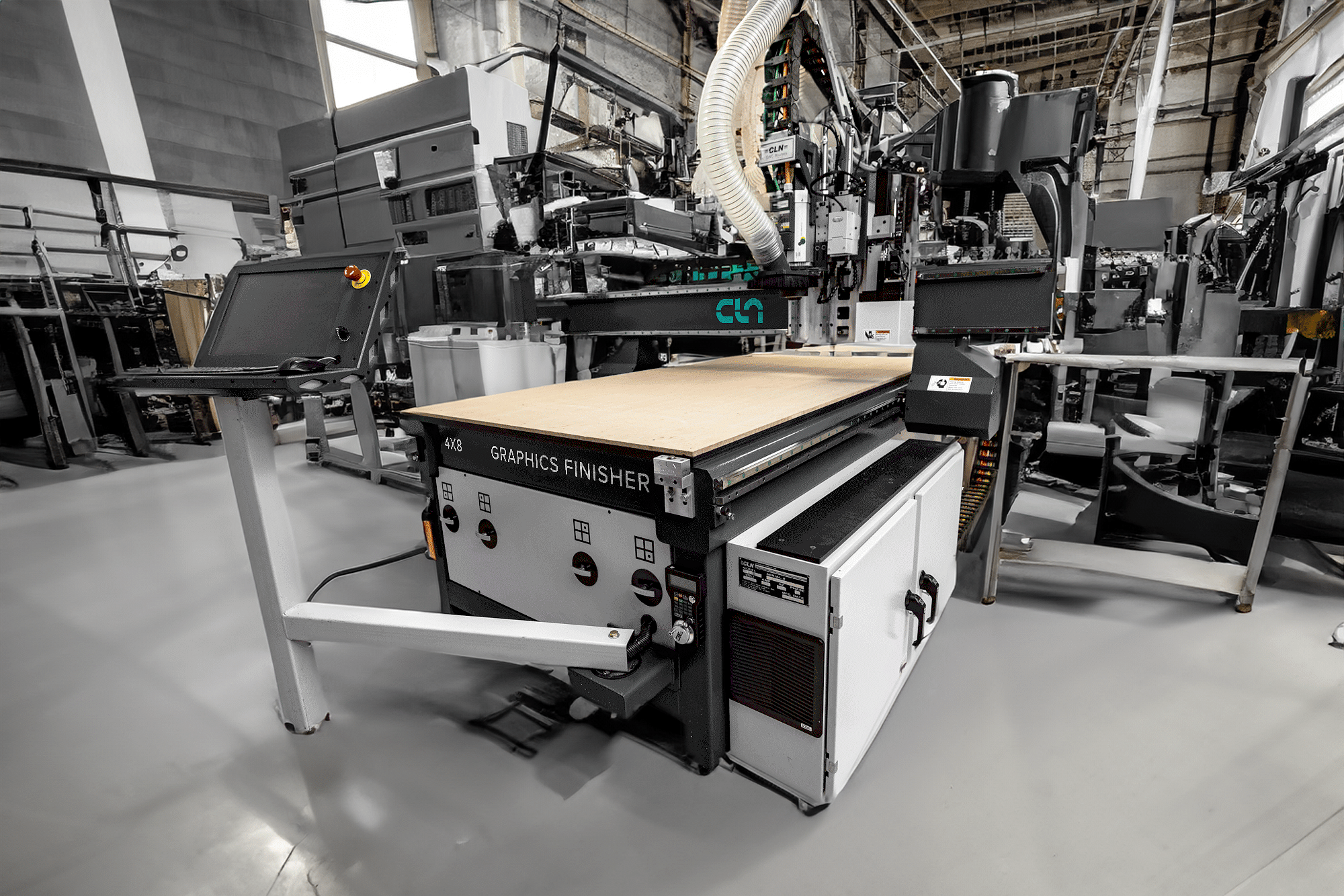

CNC Machines for Sign Making

Clear signage still draws attention faster than many online ads. Retail storefronts, event booths, and service vehicles all rely on bold graphics to guide new customers toward a sale. A CNC sign making machine turns that need into a profitable service by carving letters, logos, and artwork with digital accuracy. CLN of South Florida helps sign shops, marketing agencies, and in-house brand teams take control of production with reliable CNC routers designed especially for sign making.

Why CNC Sign Making Matters in Modern Marketing

Print alone often limits creativity, while manual cutting wastes time on intricate shapes. A CNC router for sign making reads vector files and moves the cutting bit along three axes, tracing the artwork with steady speed. Each pass follows the previous path within a hairline, which means every copy of a promotional panel or menu board maintains brand standards. Precision like this supports campaigns that demand field-ready quality on tight deadlines.

Speed also counts in marketing. Launch dates change, seasonal promotions appear overnight, and new locations need displays before grand openings. CNC sign making machines finish batches in hours rather than days, reducing lead time while freeing skilled staff for design or sales work. Shorter turnarounds let companies run limited-time offers without paying rush fees to outside vendors.

CNC Router for Sign Making: Core Features

Reliable drive motors hold tolerances that keep text crisp even on half-inch letters. Heavy steel frames reduce vibration, protecting edge quality on plastic, wood, and aluminum stock. Intuitive control software accepts common file formats such as AI, EPS, SVG, and DXF, so designers export directly from their favorite programs. Tool changers switch bits automatically, carving recessed backgrounds one minute, then drilling mounting holes the next. Dust collection keeps surfaces clean, which lengthens bit life and reduces indoor air particles.

On-board preview functions show the cut path before the first plunge, preventing costly mistakes. Operators rotate, scale, or nest parts right at the control console, maximizing sheet yield. Safety sensors pause the spindle if the guard opens, giving new users confidence during training.

CNC Wood Signs Made Easy

Natural wood remains popular for boutique brands, restaurants, and resorts that want a welcoming feel. Many creative shops use a CNC wood signs setup to carve farmhouse planks, wall art, or three-dimensional menu boards. Varying bit profiles cut clean channels for paint fills, raised borders, or textured grains that pop under stain. Production runs stay consistent, whether you make one custom welcome sign or two hundred shelf tags for a national display.

CNC Metal Signs for Maximum Durability

Aluminum and stainless steel handle storms, UV rays, and heavy traffic where plastics fade or crack. A CNC metal signs workflow slices thin sheet or mills thicker plate, letting users craft brushed plaques, back-lit channel letters, or perforated privacy panels. Powder coat or vinyl laminate finishes stick better to edges that leave the machine smooth rather than jagged. Adding a metal option expands service reach to campuses, hospitals, and government facilities that need signs to last a decade or more.

How CLN of South Florida Supports Your Success

Equipment is only the first step. CLN supplies machines, software, and full training so teams can earn revenue on day one. Installation specialists position the router, calibrate the table, and run test cuts before departure. Classroom sessions teach file prep, bit selection, and daily maintenance tasks, while video refreshers stay available online for new hires.

Lifetime technical support keeps downtime low. A phone call connects you to factory-certified technicians who troubleshoot alignment, spindle settings, or software updates. Spare parts ship quickly from the Florida warehouse, and service plans include annual tune-ups that catch wear early.

Buying direct from CLN also means access to consumables at fair prices. Coated carbide bits, collets, and vacuum hold-down pads arrive in labeled packs, so stockrooms stay organized. Material partners provide sheet PVC, hardwood plywood, or anodized aluminum cut to size, saving inbound freight on oversize pallets.

Industries That Use CNC Router Signs

-

Retail chains print vinyl faces for quick changes but rely on routed plastic backers for long-term aisle markers.

-

Theme parks deploy CNC wood signs to reinforce immersive zones, from pirate harbors to wild-west streetscapes.

-

Real estate developers install CNC metal signs at property entrances, signaling quality construction to drive-by prospects.

-

Colleges post ADA-compliant room plaques and wayfinding maps produced on a single routing platform, keeping brand colors unified across departments.

-

Marketing agencies bring CNC router signs in-house to shorten production cycles and guard client artwork.

-

Vehicle wrap shops add three-dimensional lettering kits that match fleet graphics, unlocking cross-sell revenue.

Service After the Sale

Routine checks catch issues before they slow production. CLN field technicians visit yearly to square guide rails, inspect bearings, and update control firmware. Predictive monitoring sensors track spindle hours and vibration; alerts prompt bearing lubrication or belt replacement in advance. Phone support remains available beyond warranty, and software upgrades deliver new nesting algorithms that squeeze more parts onto each sheet.

Simple Path to Ownership

Financing plans let shops preserve cash while growing capacity. CLN partners with lenders who understand equipment value, often approving credit within one business day. Payments can line up with seasonal busy seasons for tourism, holidays, or trade-show peaks. Lease-to-own options turn rent into equity, so the machine belongs to your company at term end.

Space requirements stay manageable. Most routers fit through a double doorway and draw power from a standard three-phase line, although single-phase models serve small studios. A dust collector and air compressor complete the system, both of which mount to a corner or utility closet. CLN provides floor layouts, so owners plan workflow before delivery.

Return on Investment Examples

Small shops often recover monthly financing costs by producing as few as five medium-size routed jobs per week. A single monument sign carved from aluminum composite can bring margins that exceed the payment for an entire month. In-house production eliminates mark-ups from outsourcing, increasing profit while tightening delivery schedules.

Choose CLN of South Florida for CNC Sign Making Machines

Strong branding begins with crisp visuals that stand out on any street. A CNC sign making machine gives your team control over that impression, whether you shape rustic wood or sleek metal. CLN of South Florida supplies dependable routers, thorough training, and lifetime support, ensuring every cut boosts revenue instead of stress. Call or email our sales department today for a no-obligation quote. Discover how CNC router signs can turn fresh ideas into profitable products and why businesses across South Florida trust CLN when they need the best CNC sign making solutions in the region.

Let's Talk

What Can We Do To Help You Get To The Next Level

Get in Touch:

-

Corporate: 866-264-6694

-

Sales: 561-996-5900

-

Address: 2336 Cypress Ln

Belle Glade, FL 33430