Metal Fabrication

CNC Machines for Metal Fabrication

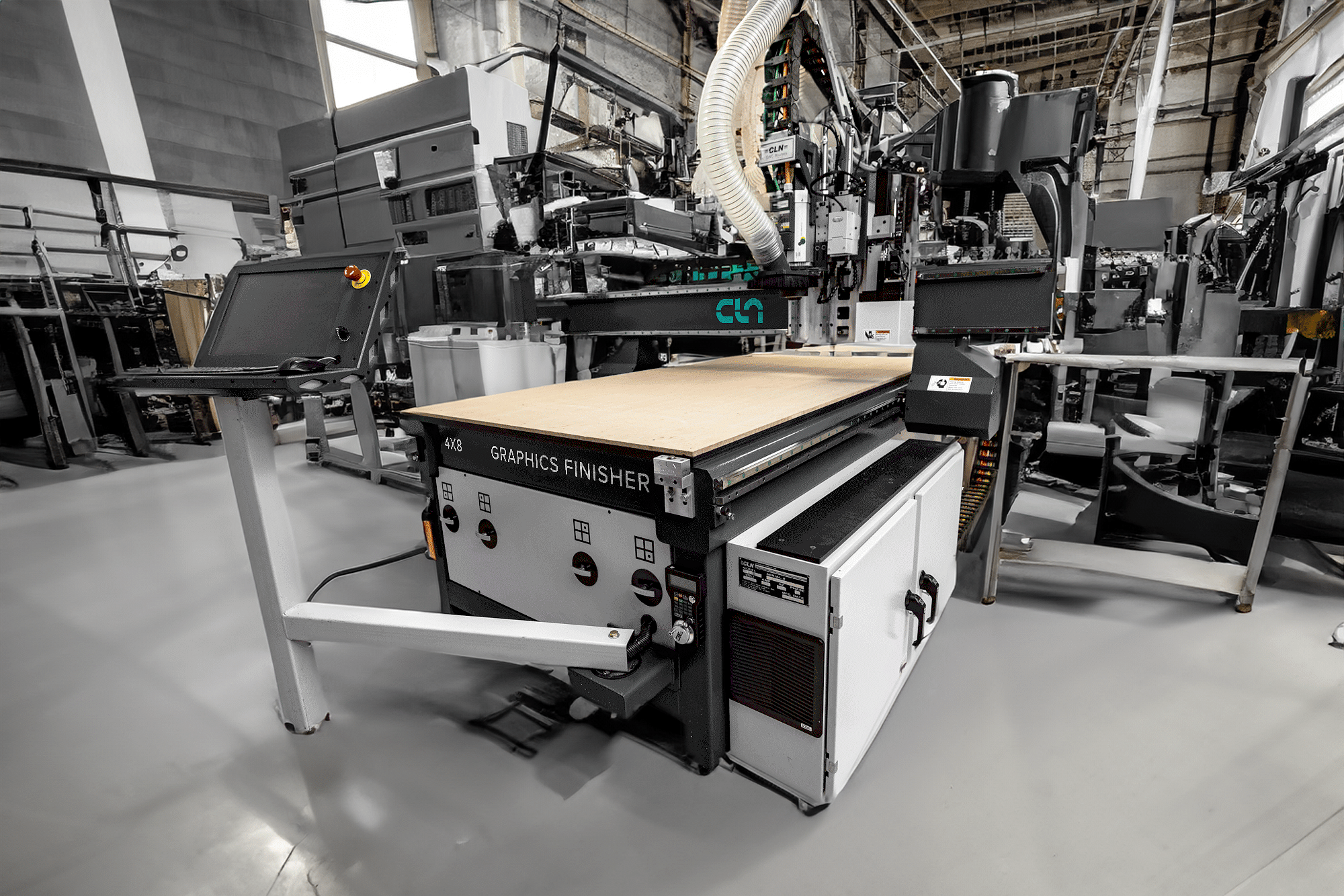

Metal parts, brackets, and enclosures demand rigid machines, accurate motion, and clean, repeatable cuts. CLN of South Florida equips manufacturers with a CNC machine for metal fabrication that balances heavy-duty mechanics with intelligent controls, nesting software, and shop-ready safety systems to keep throughput high while protecting finish quality. Teams that move to our platforms accelerate the path from prototype to production with fewer rejects, shorter cycle times, and predictable delivery dates.

Selecting the right platform is not only about horsepower. Precision depends on frame stiffness, servo tuning, and smooth toolpaths that protect edge quality during tight radii and complex contours. Our engineers help you match table size, drive technology, and peripherals to your parts and materials, which means your investment starts paying back from the first production runs.

Built for Sheet Metal from the Ground Up

CNC for metal fabrication is not a one-size-fits-all workflow. Structural steel, stainless, and aluminum respond differently to heat input, chip formation, and hold-down strategies, which is why our machines combine rigid frames, guided linear rails, and high-resolution encoders that keep position under load. The result is consistent kerf control, tighter inside corners, and flatter parts that minimize secondary work.

Thermal stability and motion smoothness matter as much as peak cutting power. Advanced motion planners maintain constant velocity through arcs and transitions, while torch height control or spindle feeds adjust in real time to sheet variations. Shops see fewer taper defects, cleaner pierces, and edges that deburr quickly, which shortens downstream finishing.

What You Can Cut and Create

A single CNC machine for sheet metal fabrication can open new lines of work across thicknesses and alloys:

- Fabricators leverage our platforms for brackets, gussets, mounting plates, frames, machine guards, HVAC panels, artistic panels, and architectural signage with repeatable precision and attractive edges.

- Mild steel, stainless, and aluminum in thicknesses appropriate to your table, with consistent kerf, minimal warping, and reliable tabbing for part retention

- Production of enclosures, trays, and chassis with accurate hole patterns that line up with downstream forming and hardware insertion

- Short-run and contract jobs that benefit from fast nesting, low setup time, and dependable repeatability across batches

CNC Machine Options for Metal Fabrication

Many shops choose CNC plasma cutters for metal fabrication because plasma offers rapid cut speeds, solid edge quality on structural steel, and favorable consumable costs. Our plasma systems pair robust gantries with precise torch height control, automatic gas regulation, and advanced pierce routines that extend consumable life while protecting finish quality. Operators gain confidence through intuitive controls, clear on-screen prompts, and job libraries that store proven parameters.

Teams working primarily in aluminum or thin non-ferrous materials often select a CNC router for metal fabrication configured for metal duty. High-speed spindles with balanced toolholders, mist or minimum quantity lubrication, and vibration-damped tables deliver clean edges and reliable slotting in aluminum plate. The same table can process composites, plastics, and wood with a tooling change and a verified toolpath, which expands your revenue without expanding your footprint.

Tooling, Fixturing, and Process Control

Cut quality improves when the right tooling meets disciplined process control. For plasma, consumable selection, pierce height, and cut amperage must align with thickness and alloy, while lead-ins and lead-outs protect corners and small features. For routing aluminum and other non-ferrous metals, flute geometry, helix angles, and coatings work together with feed and speed to manage chip load and heat. Our team dials in starter recipes for your core jobs, then trains operators to adjust safely and quickly as part geometry changes.

Fixturing is planned around part size and mix. Zoned slat beds and smart tabbing strategies keep plasma parts secure without over-tabbing, which reduces grinding. T-slot or vacuum hybrid tables for routing support thin sheet work and nested parts while minimizing chatter. Fume extraction, chip evacuation, and coolant management are specified up front, which keeps the work area clean and your operators focused.

Software and Motion Control Matter

Powerful nesting and CAM software minimizes waste while protecting features with proper kerf compensation and micro tabs. Automated lead-in strategies and corner loops reduce tip wear and prevent divots on visible edges. Post processors tailored to our controls produce smooth motion with consistent acceleration profiles, which keeps cuts clean through tight arcs and intricate patterns.

Real-time monitoring closes the loop. Torch height control senses surface variation and adjusts on the fly. Probing and calibration routines verify squareness and scale before the first production panel. Shops get reliable first-article results, then store the winning recipe so the next batch runs right away.

Buying Guide for a CNC Machine for Sheet Metal Fabrication

-

Define the Work Envelope: Match table size to common sheet formats and nesting needs, leaving enough travel for fixtures and future growth.

-

Choose the Cutting Technology: Select CNC plasma cutters for metal fabrication when speed and thickness range drive value, or specify a CNC router for metal fabrication when aluminum plate, tight tolerances, and multi-material flexibility matter.

-

Specify the Motion System: Prioritize rigid gantries, linear guides, and servo drives that hold accuracy under acceleration and thermal load.

-

Plan Extraction and Cooling: Size fume extraction for plasma, and size chip evacuation and minimum quantity lubrication for routing so edges stay clean and operators stay safe.

-

Align Controls and Software: Verify nesting, post processors, and torch or spindle control features that match your parts, alloys, and workflows.

-

Secure Service and Training: Confirm local parts, responsive support, and structured training so your team reaches steady production quickly.

Industries We Equip

Contract fabricators, OEMs, and maintenance teams rely on CNC fabricating systems for sheet metal to hit deadlines without sacrificing finish quality. Our machines help metal shops produce profitable short runs and repeat orders while keeping operators comfortable and confident on the floor no matter if it’s:

- Job shops handling mixed materials and frequent changeovers with tight promise dates

- HVAC, electrical, and enclosure builders that need accurate panels and hole patterns ready for forming and hardware insertion

- Architectural, sign, marine, and automotive suppliers producing decorative panels, brackets, and structural components with consistent edges

Return on Investment

Capital equipment earns its keep when scrap drops, cycle times shrink, and schedules hold firm. Better nesting improves yield, cleaner edges reduce grinding, and predictable parameters limit trial parts, which frees operators to focus on value-adding tasks. Shops offering CNC metal fabrication for sub-contractors gain pricing power through reliable quality, short lead times, and the ability to say yes to complex patterns.

Repeatability multiplies the benefit over time. Once a job is proven, it runs on demand with the same edge quality and dimensions, which strengthens customer relationships and supports long-term agreements. Managers gain clear data on run times and consumable use, which improves quoting accuracy and protects margins.

Why CLN of South Florida

Experience with metal cutting shapes every recommendation we make. Frames are sized for the stiffness your parts demand, not only a catalog specification, and controls are chosen for smooth motion that preserves edges on detail-rich work. Vacuum, slat, and fixturing strategies are engineered around your smallest parts and your thickest plate. Service is local, responsive, and backed by a real parts pipeline that protects your production schedule when demand spikes.

The result is a CNC machine for metal fabrication you can trust day after day. Whether you need a CNC machine for sheet metal fabrication to expand capacity or a platform that unifies plasma and routing across materials, our team aligns the machine, software, and training with your goals. Reliable performance turns into better quotes, stronger delivery promises, and fewer surprises on the shop floor.

Get Started with Top-Rated CNC for Metal Fabrication

Your next project moves faster when the right machine, workflow, and training come together. CLN of South Florida will help you evaluate parts, choose the ideal CNC machine for metal fabrication, and launch a process that delivers crisp edges and dependable throughput. Reach out today for the best CLN machines for metal fabrication and start building a more profitable, more predictable operation.

Let's Talk

What Can We Do To Help You Get To The Next Level

Get in Touch:

-

Corporate: 866-264-6694

-

Sales: 561-996-5900

-

Address: 2336 Cypress Ln

Belle Glade, FL 33430