Fusion+

More capability, built in.

Channel letters are a crucial element of storefront advertising, making up over 65% of all storefront signage. These signs are essential for attracting customers and making a business stand out. The average channel letter size is 16 inches, but the smallest letter you’d typically want to sell for storefront use is 6 inches. A 6-inch letter provides optimal impact at 60 feet and remains readable up to 200 feet away.

Financing Available

Ask About CNC Machine Financing Options.

We want to help your business realize its potential.

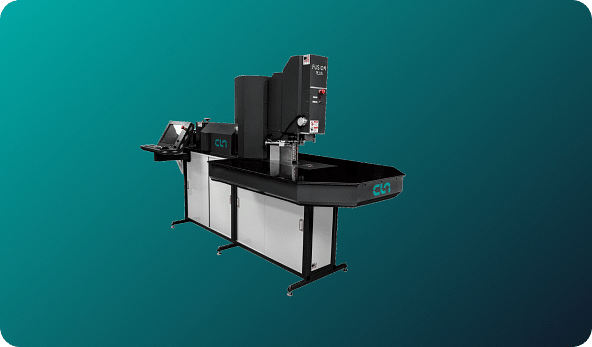

Get A QuoteThe CLN Fusion and Fusion Plus: Leading the Industry

The CLN Fusion and CLN Fusion Plus machines are game-changers in the channel letter industry. They manufacture channel letters 1/3 faster than any other machine on the market. Equipped with a dual-loop servo drive system, these machines ensure speed and accuracy, significantly enhancing the profitability of your channel letter department.

The CLN Fusion is a state-of-the-art channel letter bending machine that has set new industry standards. Its patented rotating clamping dies allow for sharper corner bends. For smooth radiuses, the machine utilizes roll forming technology, feeding the material through a roller system. Additionally, the shear is positioned at the end of the bending process, minimizing material waste. A ¼-inch drain hole punch is also included to prevent costly mistakes. The "Lights Out Operation Mode" enables the fastest job completion times, making this machine highly efficient.

Advanced Features with the CLN Fusion Plus

The CLN Fusion Plus takes innovation a step further with the inclusion of an Articulating Cutting Wheel (ACW) for materials with an inside profile, such as Letter Edge and various imported materials. This advanced feature makes the Fusion Plus versatile and capable of handling a wide range of materials, making it an indispensable tool for your production line.

For businesses with lower production levels, CLN offers the manual CLN 6″ BENDER, “the machine that started it all.” This manual bender is perfect for smaller operations or as an additional tool for less frequent bending tasks.

Why Choose Our Channel Letter Benders?

- Speed and Efficiency: Our CLN Fusion and Fusion Plus machines are designed to significantly reduce production time, allowing you to manufacture channel letters 1/3 faster than any other machine on the market. The dual-loop servo drive system ensures that your production process is not only quick but also consistent, helping you meet tight deadlines and increasing overall productivity.

- Precision: Accuracy is paramount in channel letter manufacturing, and our machines deliver unparalleled precision. The dual-loop servo drive system provides consistent, error-free bending, ensuring that each channel letter meets exact specifications. This precision reduces the need for rework, saving time and resources while maintaining high-quality standards.

- Versatility: The CLN Fusion Plus comes equipped with an Articulating Cutting Wheel (ACW), making it capable of handling a wide range of materials, including Letter Edge and many imported materials. This feature, combined with roll forming technology, allows for the creation of both sharp corners and smooth radiuses, catering to various design requirements and expanding your production capabilities.

- Cost-Effectiveness: Our machines are designed to minimize material waste and reduce costly mistakes. The end-positioned shear cuts the material only after the bending process, ensuring optimal use of materials. Additionally, the ¼-inch drain hole punch prevents errors that could lead to material wastage, making your production process more cost-effective and efficient.

- Ease of Use: From the manual CLN 6″ BENDER to the advanced Fusion machines, our products are engineered for user-friendly operation. The "Lights Out Operation Mode" on the Fusion machines allows for automated, unattended operation, freeing up your workforce for other tasks. The intuitive controls and robust design ensure that even less experienced operators can achieve professional results, making it easier to integrate our benders into your production line.

Take Your Channel Letter Production to the Next Level

Ready to revolutionize your storefront signage? Invest in our advanced CNC Channel Letter Benders today and experience unparalleled speed, precision, and efficiency. Whether you're a high-volume producer or a smaller operation, we have the right solution to meet your needs. Contact us now to learn more about our innovative channel letter bending machines and find the perfect fit for your business.

Let's Talk

What Can We Do To Help You Get To The Next Level

Get in Touch:

-

Corporate: 866-264-6694

-

Sales: 561-996-5900

-

Address: 2336 Cypress Ln

Belle Glade, FL 33430