Foam

CNC Foam Cutter Services

Modern foam projects reward teams that can move quickly, hold tight tolerances, and repeat results across batches without guesswork or rework. A CNC foam cutter delivers exactly that combination of speed and precision while keeping your production floor flexible. CLN of South Florida supplies, configures, and supports every CNC foam cutting machine we sell, which means you get equipment that matches your parts, your workflow, and your budget from day one.

What a CNC Foam Cutting Machine Does

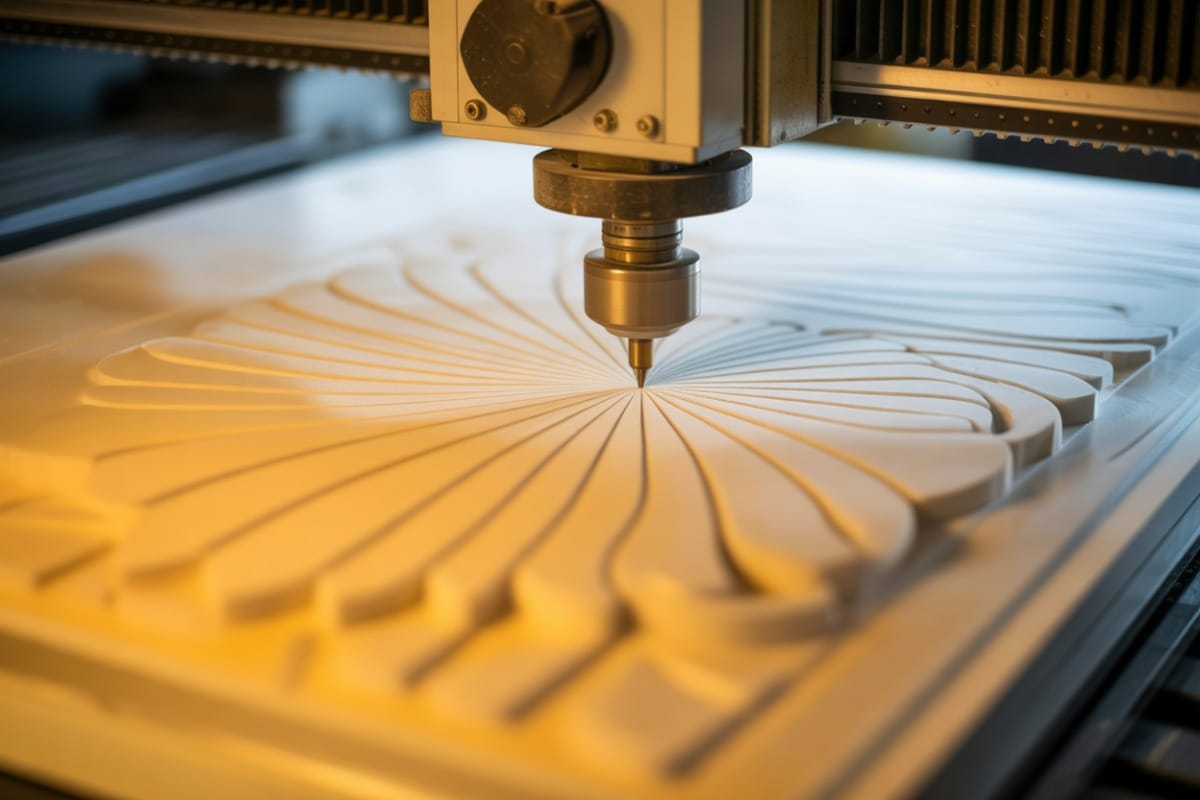

A CNC foam cutting machine interprets digital toolpaths and converts them into clean, accurate cuts through rigid or flexible foam. The system combines motion control, spindle or hot wire technology, fixturing, and specialized tooling to produce complex shapes that would be difficult by hand. Programming happens once, repeatable parts follow, and scrap rates drop noticeably.

Consistency becomes the headline advantage, yet the practicality of a foam CNC machine shows up in the details. Setup times shorten, nests improve, and operators can run multi-part panels with confidence. Projects that used to stretch over multiple days compress into hours because the workflow is stable, documented, and easy to train.

Common Foam Types and Ideal Fits

CNC foam cutting thrives across a wide range of materials. Expanded polystyrene, extruded polystyrene, polyurethane, and polyethylene all machine well with the right tooling and feeds. High-density foam boards used for patterns, casting positives, and architectural elements remain very popular with our customers.

Composite shops frequently pair a CNC machine for foam with laminating or layup operations. Sign makers appreciate how a CNC foam router machine carves crisp letters and dimensional logos that paint cleanly. The same platform can also handle packaging inserts, protective end caps, and custom dunnage for shipping.

Cutting Technologies That Match Your Parts

Two primary technologies drive most foam work. A router-based foam cutter CNC uses a rotating tool to mill pockets, profiles, and 3D reliefs with excellent edge quality. A hot wire configuration slices through foam with a heated filament, ideal for contours, tapers, and wing cores where speed and smooth faces matter.

Hybrid machines expand your range even more by adding knife or oscillating tool heads for specialty cuts. Shops that handle both intricate carvings and long straight sections can select a CNC foam cutting machine with fast tool changes, which keeps cycle times short. CLN of South Florida helps you map each part family to the technology that will finish it faster and cleaner.

Accuracy, Finish, and Repeatability

CNC foam milling shines when you need close tolerances over large panels. Rigid frames, quality linear guides, and balanced spindles work together to keep vibration down and surface finish up. Proper chip evacuation and vac tables prevent part movement, which preserves dimensions even on thin sections.

Repeatability grows more important as batches scale. Once your post-process sanding or sealing steps are dialed in, a CNC foam milling machine reproduces that result without drift. Your team gets reliable outcomes and fewer surprises across shifts.

OUR CNC MACHINES CUT

Software Workflow That Keeps Jobs Moving

The workflow starts with your CAD model, moves through CAM to generate toolpaths, and concludes with a controlled program at the machine. Good CAM for CNC foam cutting focuses on stepdowns, climb versus conventional strategies in foam, and smoothing that reduces tool marks. Tool libraries and presets shorten programming for future runs.

Operators benefit from simple on-machine controls, clear work offsets, and saved macros for common operations. CLN of South Florida can mirror your naming conventions, directory structure, and backup routines so that jobs remain organized. Training emphasizes how to tweak feeds and speeds in foam without risking part quality.

Who Benefits From a Foam CNC Machine

Architectural fabricators rely on CNC foam cutting for themed environments, cornices, capitals, and ornamental surfaces that paint beautifully. Aerospace and marine teams machine plugs, cores, and patterns that later become molds. Industrial packagers tailor protective inserts that lock products in place during transit while keeping material use efficient.

Sign shops carve dimensional letters, badges, and routed faces that stand out after coating. Educational makerspaces and prototype labs value the quick idea-to-part loop that a foam CNC milling machine enables. Each of these groups gains the same thing in the end, a reliable way to transform digital designs into accurate foam parts.

Why Choose CLN of South Florida

CLN of South Florida pairs proven machines with hands-on integration, which helps you get productive faster. Our team reviews your part mix, estimators’ targets, and operator skill levels to match a CNC foam cutter to your real-world constraints. Training focuses on practical wins such as fixture design, safe tool changes, and fast troubleshooting.

Support continues after installation through phone guidance, remote diagnostics, and on-site visits when needed. Replacement tooling, collets, and wear parts stay available, which protects your uptime. You get a partner who tracks your success metrics and helps you raise them over time.

From Quote to First Good Part

1) Discovery and Fit Check: We review parts, densities, tolerances, coatings, and batch sizes, then confirm the right CNC foam cutting machine and table size.

2) Proof of Capability: We run representative samples, verify edge quality and cycle time, and document the setup for repeatability.

3) Configuration and Delivery: We prep motion control, tooling kits, extraction, and workholding so the floor is ready when the machine arrives.

4) Installation and Training: We align, level, test, and train your operators on programming, offsets, tool changes, and safe daily checks.

5) Ramp and Optimize: We refine feeds, speeds, and nests, capture standard work, and set maintenance intervals that keep output high.

Financing Pathways That Fit the Plant Budget

Every manufacturer has a preferred capital strategy, so the project should meet your financial framework rather than force a single path. Many clients choose to own the system to capture incentives and asset value, while others prefer structured financing that preserves cash for core operations. Federal incentives and bonus opportunities can strengthen the case, and utility programs may add performance-based benefits.

Potential approaches include:

- Capital purchase with incentives captured by the owner.

- Operating leases structured to align payments with production seasons.

- Third-party ownership models that trade upfront cost for predictable energy pricing.

Feature Snapshot for CNC Foam Cutting

Rigidity where it matters, including steel gantries and precision linear motion for crisp edges and true pockets.

Router, hot wire, and optional knife heads to cover profiles, contours, and 3D relief without switching platforms.

Vacuum zoning, low-profile clamps, and custom jigs that hold delicate foam securely while avoiding dents or warps.

Tooling, Feeds, and Speeds

Router tooling for foam favors sharp single-flute and O-flute geometries that evacuate chips without melting edges. Larger diameters help clear pockets quickly while small finishing tools polish fine details. Hot wire setups emphasize stable temperature control and steady traverse rates for smooth faces.

Feed and speed selection in foam leans toward higher surface speeds with controlled stepdowns. It becomes important to watch part temperature and maintain airflow around the cut. CLN of South Florida provides starting recipes for each foam family and then tailors them as your parts demand.

Specifications and Options That Matter

Bed size, Z travel, and gantry clearance determine what you can cut and how quickly you can fixture a board. Controller choice affects how easily you store offsets, call subroutines, and recover from power events. Extraction capacity and filtration become important in router-heavy environments where airborne particulates must be minimized.

Optional probes, cameras, and alignment tools shorten setups and reduce human error. Remote monitoring helps supervisors watch job status without hovering over the machine. CLN of South Florida helps you select only the options that raise your return rather than crowding the quote with features you will not use.

Safety and Compliance

CNC foam cutting demands safe habits and clear procedures. Guards, interlocks, and e-stop locations protect operators while allowing quick access for tool changes. Proper handling and storage of foam stock, particularly in hot wire applications, keep the work area safe and tidy.

Electrical and ventilation standards must be respected during installation. CLN of South Florida aligns your machine placement and extraction with local requirements. Documentation and training ensure your team understands both the rules and the reasons behind them.

Budgeting, Financing, and ROI

Capital planning improves when cycle times, labor hours, and scrap rates are quantified before the purchase. A CNC foam milling machine often replaces multiple manual steps, which simplifies staffing and scheduling. Payback periods shorten as repeat orders flow through the same proven setup.

Financing programs may allow you to start producing revenue while preserving cash for material and headcount. CLN of South Florida can structure a package that fits seasonal production swings and growth plans. The result is a machine that pays for itself while elevating your reputation for quality and speed.

Integration With Your Production Flow

A CNC foam cutter becomes even more valuable when it fits cleanly into upstream design and downstream finishing. File standards, revision control, and shared libraries eliminate missing-tool errors and version mix-ups. Clear labeling and staging practices help finished parts reach coatings, lamination, or shipping without delay.

Data capture from the controller can feed dashboards that track utilization and on-time performance. Supervisors gain a real picture of capacity that guides scheduling and sales commitments. These small controls add up to a smoother plant and happier customers.

Training That Builds Confidence

Operator confidence rises when training is grounded in your actual jobs. We teach fixture selection for large and small panels, practical vacuum zoning, and how to prevent chatter or lift. New hires learn the why behind each step, which shortens the time between shadowing and independent operation.

Programming workshops focus on efficient toolpaths, predictable finishes, and naming standards that keep files tidy. Leads get guidance on preventive maintenance and quality checks that catch drift early. Your team leaves with skills that translate directly to throughput.

Get a Custom Quote for a CNC Foam Cutter Today

Choose CLN of South Florida for a CNC foam cutter that arrives configured for your materials, your tolerances, and your throughput goals. Tell us about your parts and timelines, and we will recommend a CNC foam cutting machine that delivers sharp edges, clean finishes, and reliable repeatability. Reach out to schedule samples, confirm fit, and start producing first-good parts with a foam CNC machine built for your shop.

Let's Talk

What Can We Do To Help You Get To The Next Level

Get in Touch:

-

Corporate: 866-264-6694

-

Sales: 561-996-5900

-

Address: 2336 Cypress Ln

Belle Glade, FL 33430