Plastics

CNC for Plastics

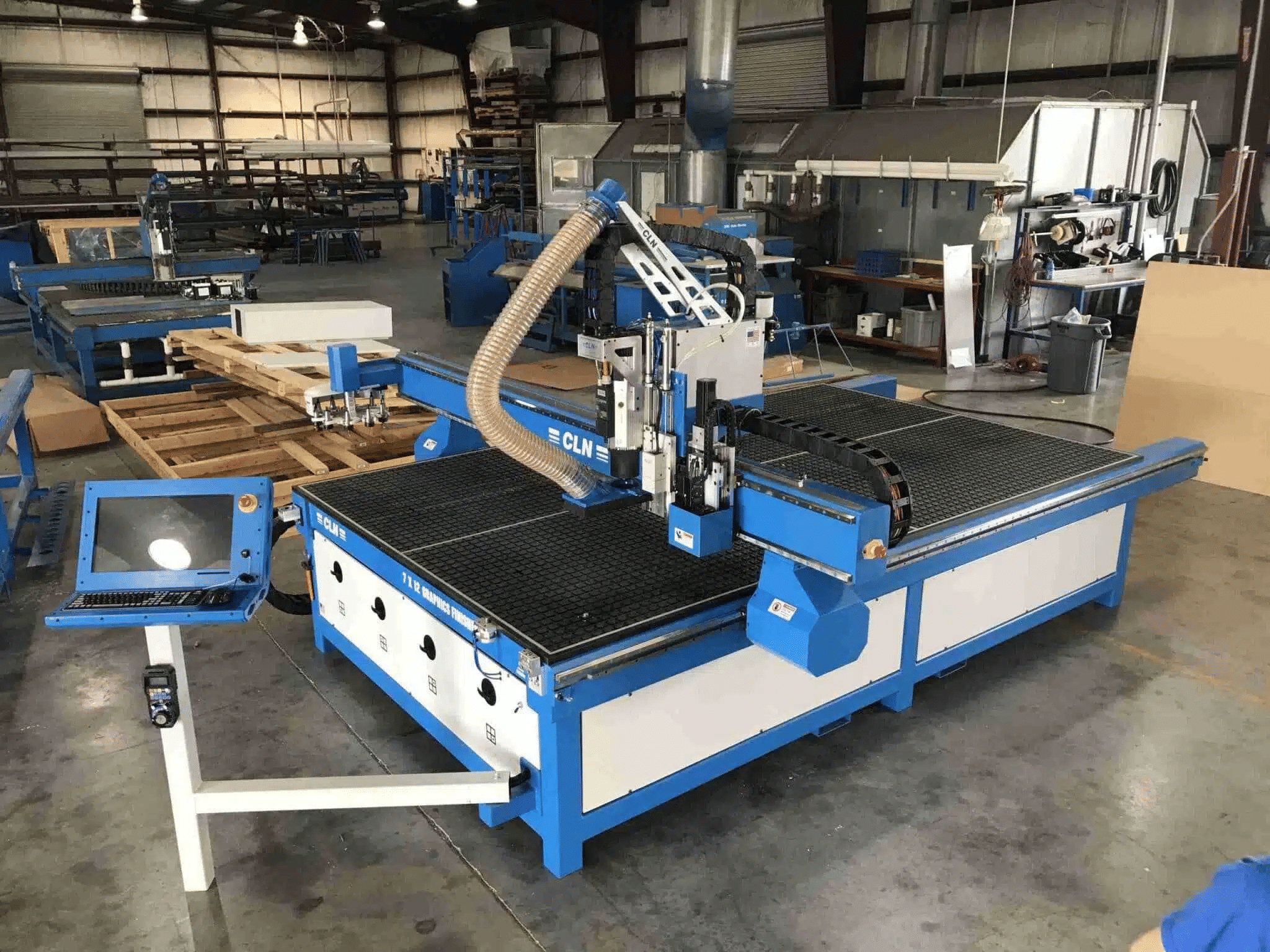

Plastic parts, displays, and enclosures demand clean edges, tight tolerances, and repeatable results. CLN of South Florida supplies CNC machines for plastics that are purpose built for thermoplastics and engineered resins, pairing rigid mechanics with software, tooling, and vacuum systems that keep heat under control while protecting your finish. Teams that upgrade to our platforms move from prototype to production with fewer rejects, faster cycle times, and confident delivery dates.

Built for Plastics from the Ground Up

CNC machining for plastics is not a metal workflow applied to different materials. Heat management, chip evacuation, and surface protection require a machine that holds position precisely while clearing chips completely. The frames of our machines resist vibration, spindles maintain stable torque at high revolutions per minute, and tables generate uniform hold-down across thin sheets or nested parts. Additionally, toolpaths are executed smoothly to avoid shocking brittle materials, while controls allow quick adjustments to feed and speed as resin grades change.

Materials and Applications

- Acrylic, cast and extruded, for crystal clear edges on displays and guards

- Polycarbonate for impact resistant covers and housings

- ABS and ASA for durable enclosures and instrument panels

- HDPE and UHMW for wear strips, guides, and food processing parts

- Acetal, often referred to as Delrin, for precision bushings and manifolds

- PVC and CPVC for panels and fluid handling components

- Nylon and filled nylons for structural parts

- PTFE and high performance fluoropolymers where chemical resistance matters

- Polypropylene for trays, packaging components, and labware

Shops rely on our machines for signage, point of purchase fixtures, machine guards, electrical panels, jigs, and small to mid volume production runs that do not justify molding.

Tooling and Process Support

Performance in CNC for plastics depends on the right cutters and a disciplined process. Single flute O cutters improve chip flow in acrylic and polycarbonate, polished upcut tools keep burrs low in HDPE, and specialized geometries reduce stress in filled resins. Our team helps you match flute count, helix, and coatings to the job, then sets starting feeds and speeds that limit heat while preserving throughput. Fixturing, onion skin strategies, and climb versus conventional passes are dialed in during commissioning, which shortens the path to production quality results.

What Sets CLN of South Florida Apart

Experience with plastics machining shapes everything we recommend. Machine frames are matched to the stiffness your materials demand, not just a catalog specification. Software and motion control are selected to run smooth arcs and consistent ramps, which matters for optical surfaces. Vacuum strategies are engineered around your smallest parts, not only full sheet processing. Service coverage is local, responsive, and backed by a real parts pipeline, which protects your production schedule during peak demand.

Buying Guide for CNC in Plastics Shops

Define the Work Envelope

Choose a table that matches your common sheet sizes and allows sensible nesting. Oversizing slightly can simplify fixturing and improve yield.

Right Size the Spindle

Plastics benefit from high revolutions per minute and stable torque. Select power that supports your thickest materials without forcing slow feeds.

Plan for Hold Down

Zoned vacuum with generous flow makes thin sheet work reliable. Consider supplemental fixtures for small parts and repeat jobs.

Prioritize Extraction

Clear chips quickly to control heat and maintain edge quality. A well matched dust collector is as important as the spindle.

Invest in Training

Programming, tooling selection, and setup discipline pay back quickly. Teams that learn the why behind settings recover their time during the first projects.

OUR CNC MACHINES CUT

Industries We Equip

- Sign and graphics producers that need crisp lettering and polished acrylic edges

- Machine builders that require durable guards and covers with accurate hole patterns

- Consumer goods companies producing short run enclosures and fixtures

- Medical and laboratory teams machining trays, plates, and housings with clean finishes

- Food and beverage processors using wear resistant and easy to clean plastics

- Electrical and controls integrators cutting panels and labeling in one workflow

Service, Training, and Lifecycle Support

A successful CNC purchase includes everything after the machine arrives. Commissioning confirms accuracy, operator training builds confidence, and preventive maintenance keeps uptime high. Tooling bundles and starter programs are provided for your most common plastics, which accelerates ramp up. We offer phone support to resolve practical questions quickly, while onsite assistance is available when you need a partner at the machine for educational purposes.

Return on Investment

Capital equipment pays back when scrap falls, cycle times shorten, and customer lead times improve. Shops that replace manual routing or aged equipment see immediate gains in consistency and throughput. Secondary operations like hand polishing can be reduced through the right spindle, cutter geometry, and motion blend, which shifts labor to higher value tasks. Reliable scheduling and repeatable quality support stronger pricing and longer customer relationships.

Top-Rated Woodworking CNC Routers from CLN South Florida

Projects succeed when the right machine, workflow, and training align. CLN of South Florida helps you evaluate parts, select the best CNC for plastics configuration, and implement a process that delivers clean edges and predictable output. Reach out to us today so that we can start molding the future together!

Let's Talk

What Can We Do To Help You Get To The Next Level

Get in Touch:

-

Corporate: 866-264-6694

-

Sales: 561-996-5900

-

Address: 2336 Cypress Ln

Belle Glade, FL 33430